This will be the first of a 2 part case series on how we are using this rapidly growing technology to plan surgery in incredible detail in the virtual world. This means that before any patient undergoes a surgical procedure, implants and cutting guides can be designed and custom made to ensure perfect placement of bone cuts and implants. Human error is eliminated and surgical time is reduced all of which means even better outcomes for patients. The only limit to this technology is the imagination of the team involved in finding solutions to surgical problems.

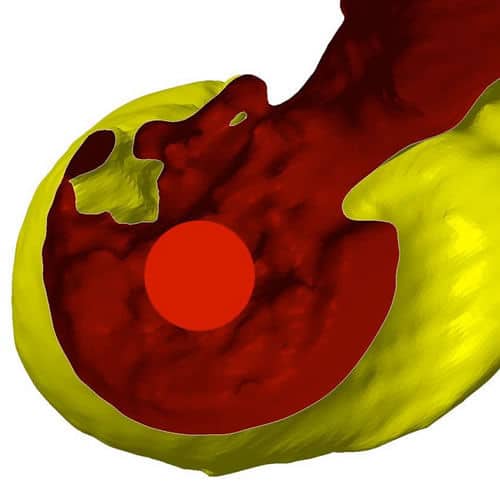

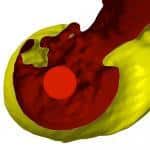

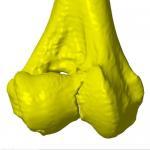

This case was a seven month old Labrador with Humeral Intercondylar Fissure. The fissure can be seen on the first image as a crack extending from the joint surface up towards the supratrochlear foramen. This poor chap was very close to suffering a catastrophic elbow fracture.

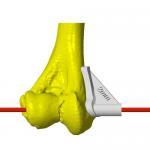

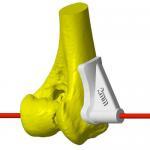

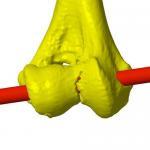

You can see from subsequent CT images (provided by Northwest MRI & CT), how a guide can be created that fits perfectly to the contour of the bone on the medial epicondyle of the humerus. This means that in surgery, the risk of placing the screw at a less that ideal trajectory is eliminated.

Perfect screw placement – first time, every time!

The virtual world then becomes reality in theatre, the guide fits perfectly to the bone. The screw is placed and bone graft is injected to encourage bone union across the fissure.

The final X-ray images really highlight the benefit of this technology… We don’t think that screw could look much better!

Northwest MRI & CT were happy to be part of this pioneering case undertaken by Gilding Orthopaedics with the help of Vet 3D.